EDM (Electrical Discharge Machining) machines are essential for high-precision machining, primarily used for shaping hard metals. They work by applying electrical discharges to remove material from the workpiece. Common types include Wire EDM, Sinker EDM, and Hole Drilling EDM, each specialized for different tasks. These machines are ideal for intricate shapes and tight tolerances in industries like aerospace and automotive.

EDM (Electrical Discharge Machining) machines are vital in achieving precise, intricate cuts in hard metals. These machines work by generating controlled electrical discharges to erode material. With applications across various industries, EDM machines excel in creating complex shapes with high accuracy and minimal material waste.

EDM machines offer unmatched precision and versatility, allowing manufacturers to create complex geometries with exceptional accuracy. The right EDM machine ensures a more efficient and cost-effective machining process, perfect for high-precision industries like aerospace and automotive.

Manisha Singh

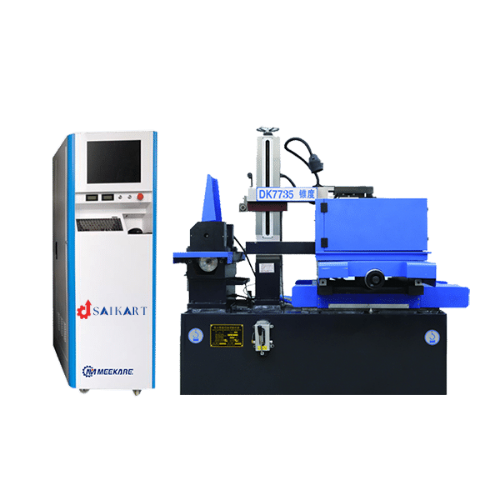

EDM Machines

Feb 02, 2025

Surat, Gujarat - 394230

EDM Machines Empower Your Manufacturing with Unmatched Accuracy and Efficiency for Complex Applications.

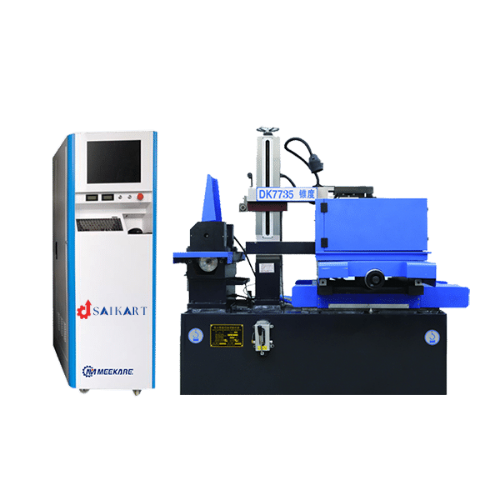

EDM machines use electrical discharges to precisely remove material from a workpiece, allowing for intricate machining.

Wire EDM uses a thin wire to cut through materials with high precision, ideal for detailed and intricate designs.

Sinker EDM uses an electrode to create cavities, while Wire EDM uses a wire for cutting through materials.

EDM is commonly used in aerospace, automotive, mold-making, and tooling industries for high-precision parts.

EDM machines can process hard metals, including titanium, carbide, and tool steel.

While requiring skilled operators, modern CNC EDM machines have simplified controls for easier use.