EDM cutting parts are crucial components used in Electrical Discharge Machining for producing intricate cuts and complex shapes. These parts include electrodes, cutting tools, and other specialized components that ensure precision and efficiency in machining processes. EDM cutting parts are typically made from materials that can withstand the heat and wear generated during the discharge process, ensuring durability and accuracy.

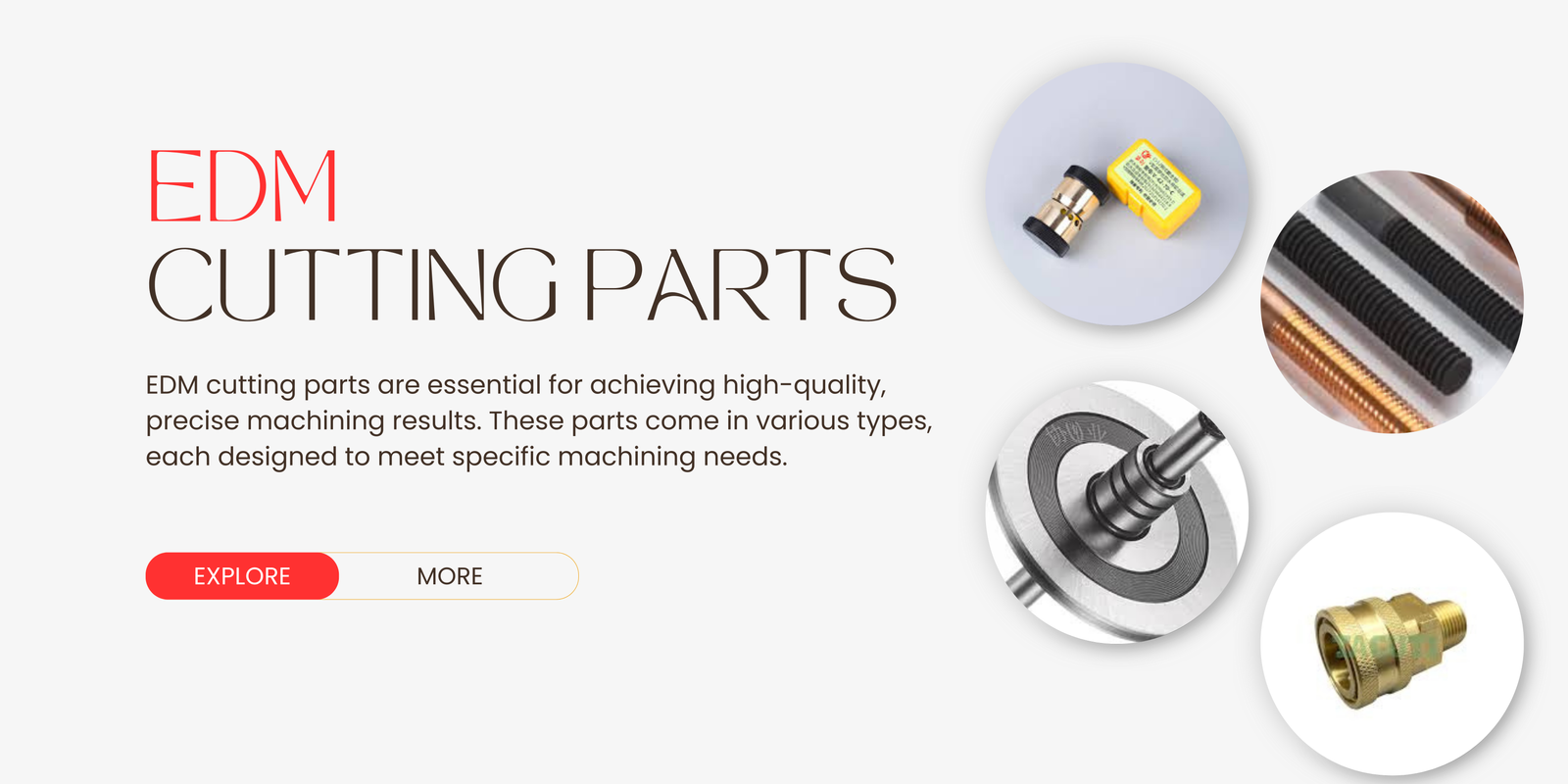

EDM cutting parts are essential for achieving high-quality, precise machining results. These parts come in various types, each designed to meet specific machining needs. The selection of appropriate parts, such as electrodes, tool holders, and other specialized components, ensures that the EDM process runs smoothly and efficiently, providing accuracy and longevity to the operation.

Choosing the right EDM cutting parts is vital for ensuring high-precision machining and extending the life of your equipment. These parts not only optimize the performance of your EDM machines but also play a crucial role in achieving intricate designs with minimal errors. Whether you’re working with electrodes, tool holders, or other specialized components, selecting quality parts tailored to your needs can drastically improve operational efficiency, reduce wear and tear, and ensure superior results in complex machining processes.

Manisha Singh

EDM Cutting Parts

Feb 02, 2025

Surat, Gujarat - 394230

“Empowering Precision Machining – Our EDM Cutting Parts Deliver Unmatched Quality, Durability, and Performance.”

EDM cutting parts include electrodes, tool holders, and other components used to perform precise cuts in hard materials.

EDM electrodes are typically made from copper, tungsten, or graphite to withstand the high heat of electrical discharges.

These parts ensure precise, high-quality cuts by optimizing the electrical discharge process.

Yes, EDM cutting parts can be customized based on the specific needs of the machining process.

The longevity of EDM cutting parts depends on the material used and the frequency of use, with some lasting for many machining cycles.

Electrodes are used to create sparks that erode the material, enabling precise shaping and cutting during the EDM process.