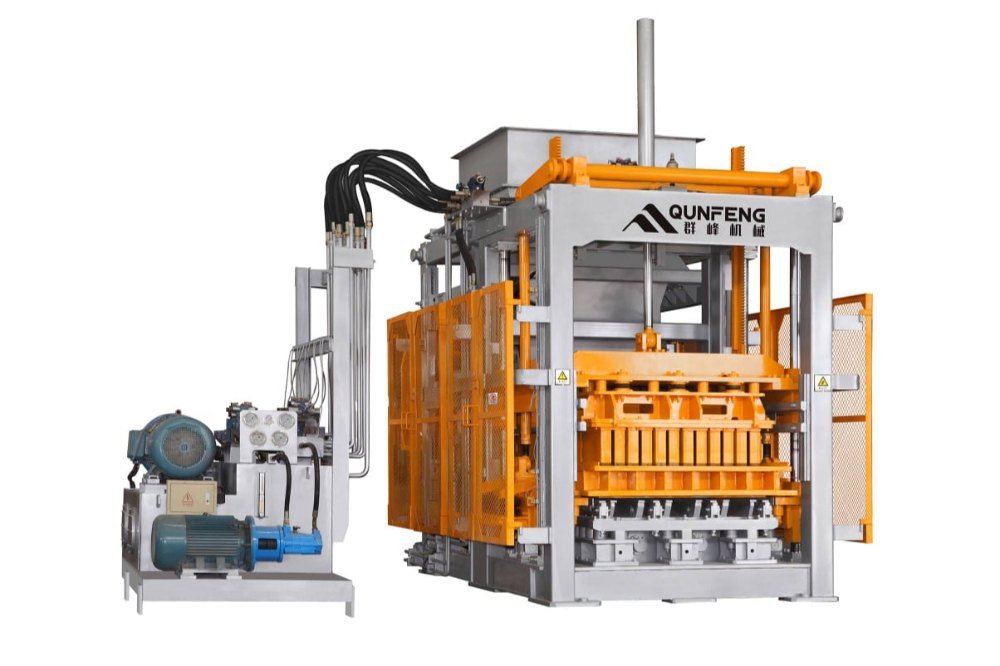

Automatic brick-making machines streamline the process of producing high-quality bricks for construction, offering precision, efficiency, and cost-effectiveness. These machines automate the brick production process, allowing for high output and consistent quality. Ideal for large-scale production, they handle tasks such as mixing, molding, and pressing with minimal manual labor. By using innovative technology, they ensure uniformity in size, shape, and strength, reducing errors and wastage in the manufacturing process.

Automatic brick-making machines come in various types, each designed to cater to specific brick production needs. These machines differ in their capabilities, from creating fly ash bricks and concrete blocks to paving stones and interlocking blocks. Some machines operate with high pressure for stronger bricks, while others offer vibration techniques for better shaping. Each type is optimized for a particular production method, allowing businesses to choose the right machine for their desired output.

With automatic brick-making machines, construction businesses can increase production capacity while ensuring consistent quality. These machines significantly reduce labor costs and improve the efficiency of the manufacturing process. Whether for fly ash bricks, concrete blocks, or other building materials, choosing the right automatic machine can optimize operations and contribute to faster project completion.

Manisha Singh

Automatice Brick Machine

Feb 02, 2025

Surat, Gujarat - 394230

Our Automatic Brick Making Machines Deliver Efficiency, Quality, and Innovation.

It is a machine that automates the entire brick-making process, from mixing to molding, ensuring high-quality production with minimal manual labor.

These machines can produce fly ash bricks, concrete blocks, paving blocks, and other types of construction bricks.

It automates processes like molding, pressing, and curing, reducing manual intervention, speeding up production, and ensuring consistency in brick quality.

Common materials include fly ash, cement, sand, and other aggregates, depending on the machine type and the desired brick specification.

Regular maintenance involves checking for wear and tear, lubricating moving parts, and ensuring proper cleaning of molds and mixing components.

Yes, these machines are designed for high-volume production, making them suitable for large-scale construction projects.